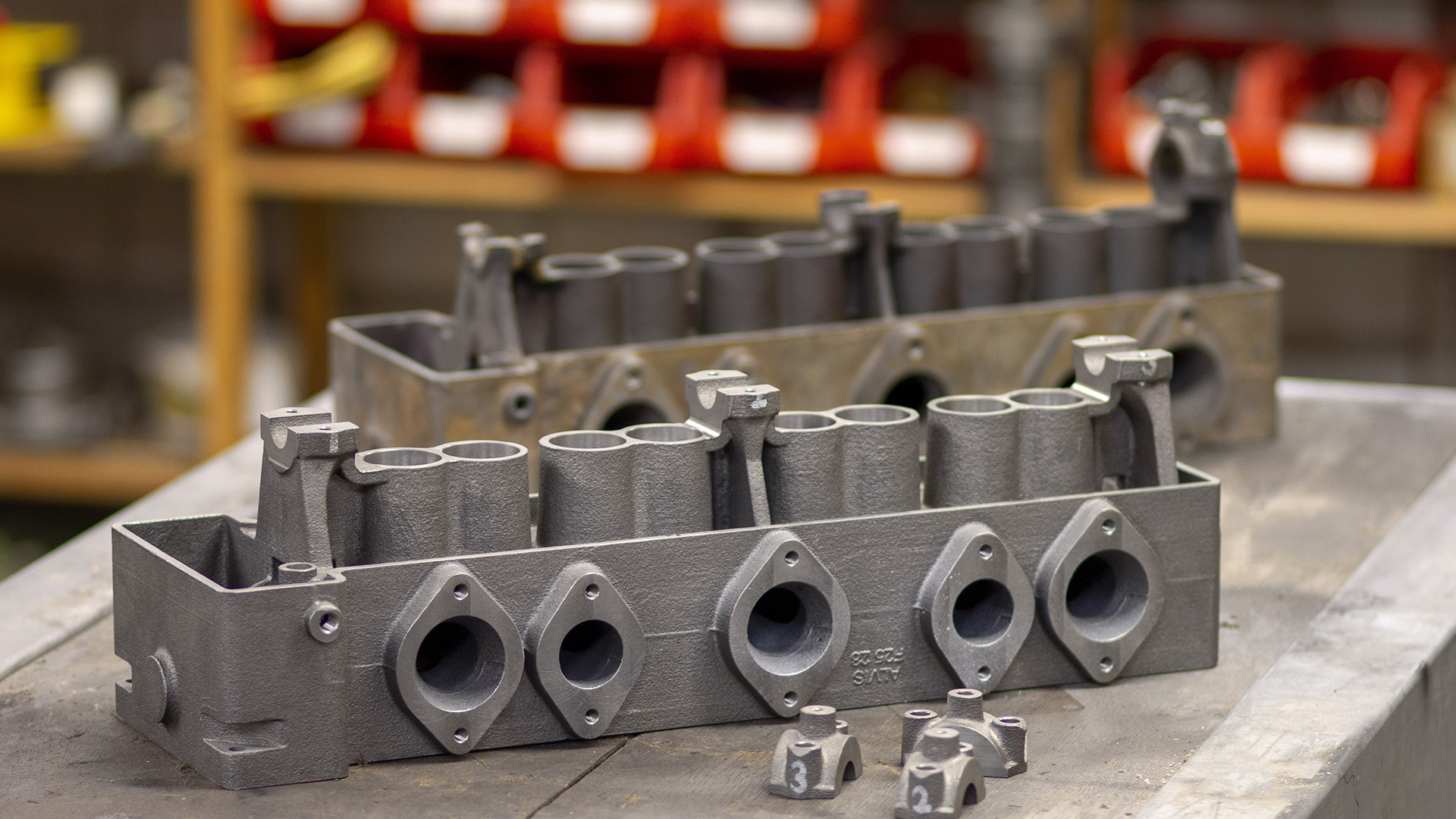

Coenradie creates a brand new cylinder head of a 90 year old model

The first step was to make a 3D scan of the original, damaged cylinder head with the structured light scanner. In order to obtain a complete 3D mesh of the cylinder head, we captured the geometry of the internal channels using silicone casts. With the 3D mesh as a reference, we started the reverse engineering in our CAD system Siemens NX. The ‘design intent’ (the original design idea) had to be reflected in the new design as much as possible. Some improvements have been made at the request of the customer. As a check, a comparison was made several times between the CAD model and the 3D scan during the design process. After completing the 3D-CAD model, we made drawings for casting and machining. Due to the small series, a company specialized in 3D sand printing has cast a number of cylinder heads based on our CAD models and drawings. Finally, the new cylinder head was scanned and compared again with the 3D-CAD model to track down any deviations between the two.

Get in touch with us, call +31 (0)499 – 577 202 and ask for Ruud Steijvers

Get in touch with us, call +31 (0)499 – 577 202 and ask for Ruud Steijvers