Slide Background

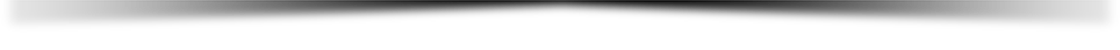

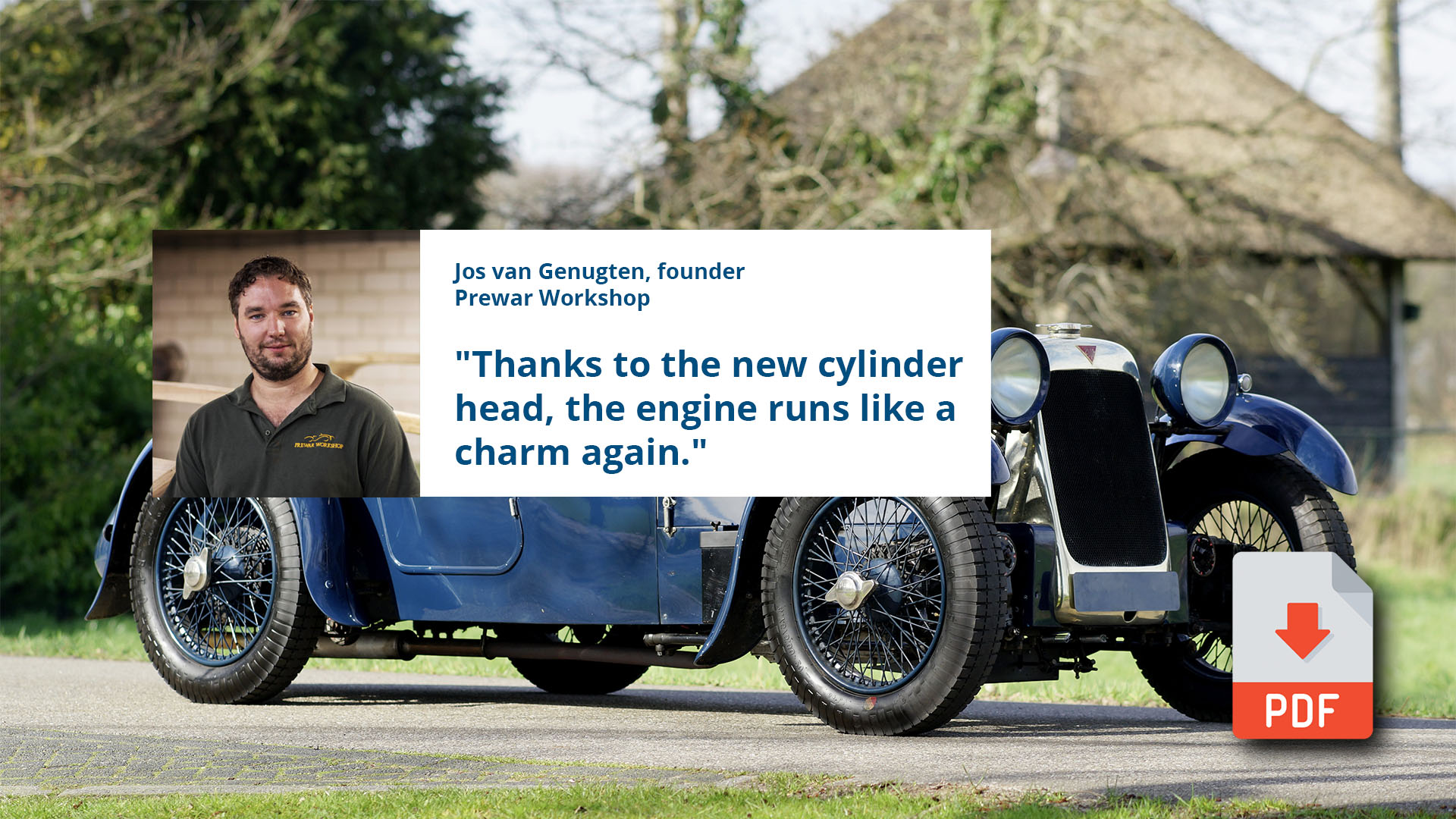

Jos van Genugten, founder Prewar Workshop

"Thanks to the new cylinder head, the engine runs like a charm again."

background photo: Marc Vorgers

Slide Background

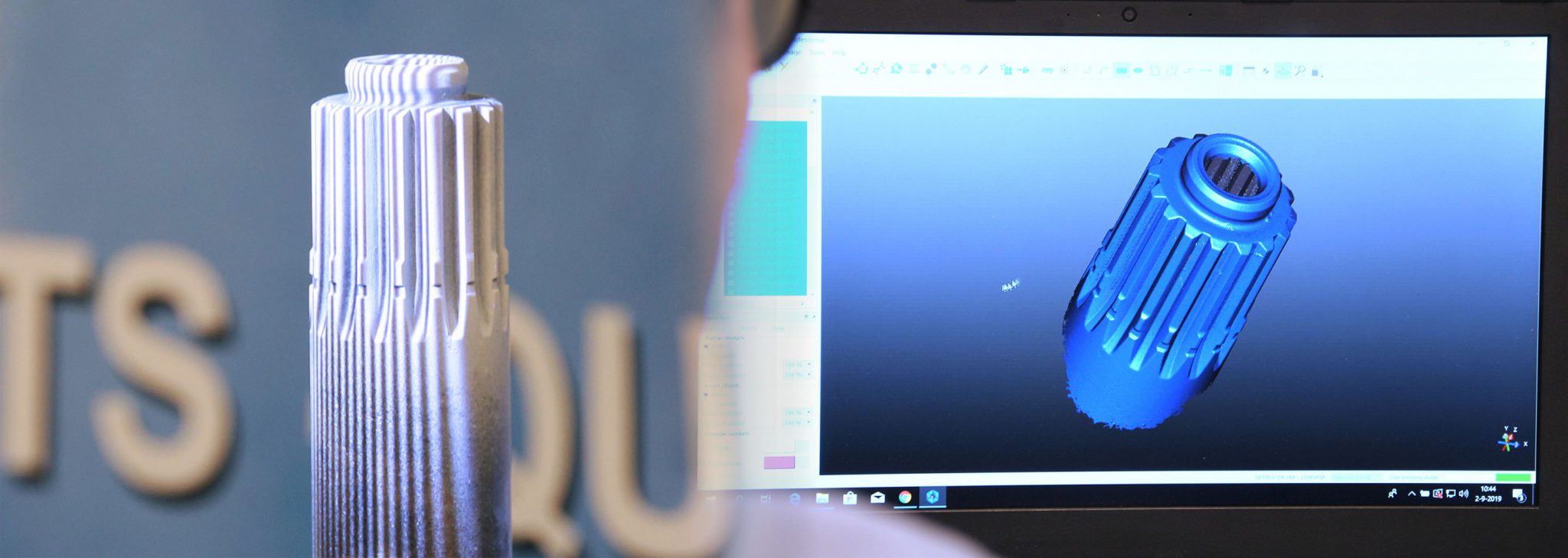

Koen Hagenaars, Operations Manager Bradford Engineering

“Rocket engines for a satellite require utmost precision.”

Slide Background

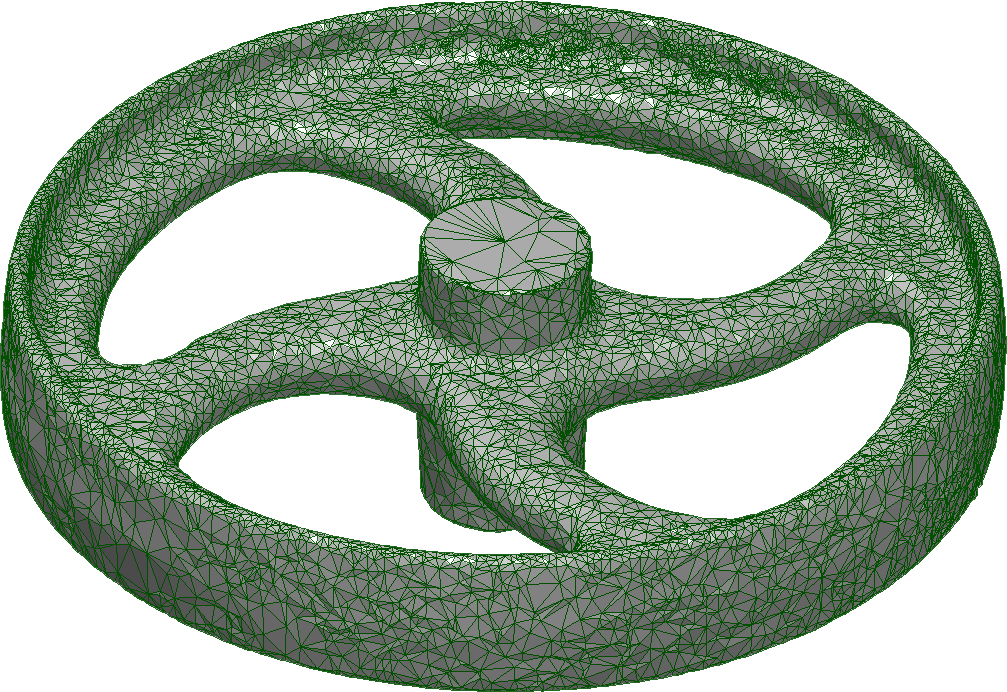

Kristina Radovic, Project Manager DPI Injection Moulding

“For the production of car seats for children only the best is good enough.”

Slide Background

Rinus Bos, Lead Engineer Aviation Glass & Technology

“For airplane mirrors we absolutely need to have a flawless image."